In industrial and commercial electrical systems, modularity is no longer a “nice to have.” It has become a fundamental requirement to meet increasing needs for flexibility, fast installation, simplified maintenance and system scalability. For electrical designers, installers, and system managers, and even for those approaching the topic for the first time, it is essential to rely on solutions that are at the same time pre-engineered, efficient, and intelligent throughout the design phase.

The busbar trunking systems manufactured by Graziadio & C., ranging from 25 to 6,300 A, represent an established Made in Italy solution for the safe and efficient distribution of electrical power.

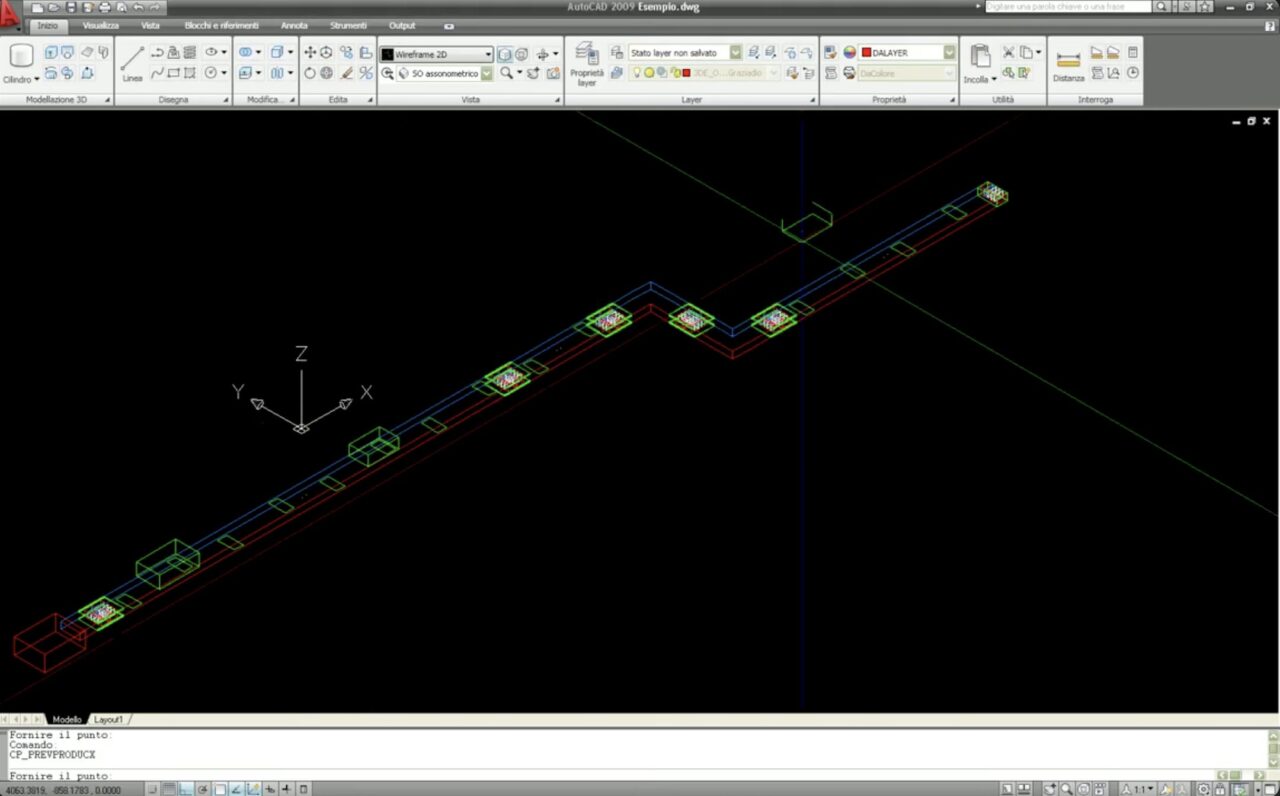

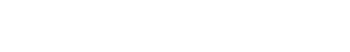

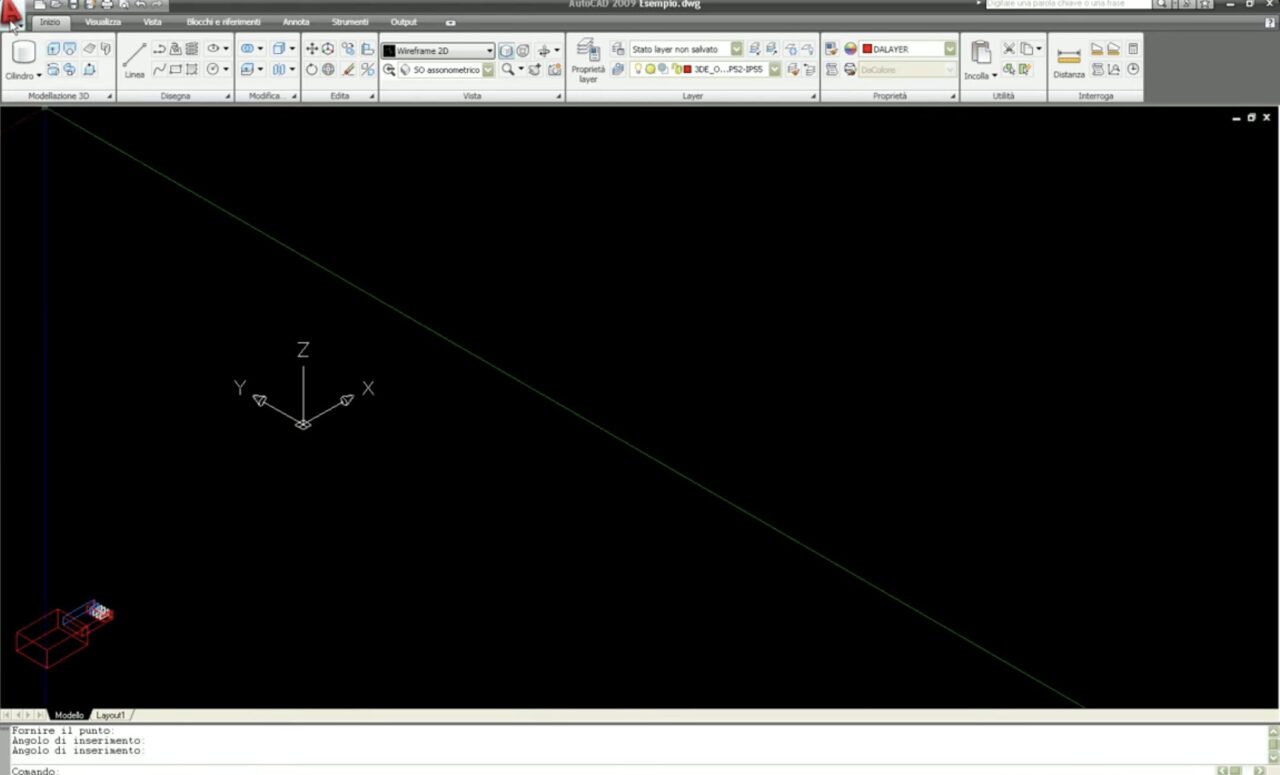

To support engineers and technical offices in the layout and system design process, Graziadio has developed BlindoCad: a modern software integrated within AutoCAD (and compatible with other CAD environments) that enables 2D and 3D modeling of busbar systems, allowing users to configure straight sections, elbows, end feeds, tap-off boxes, supports and accessories, while automatically generating the Bill of Materials (BoM).

This article aims to guide even those unfamiliar with busbar systems or CAD-based electrical design tools. You will discover why modular system design offers significant advantages, how to use BlindoCad effectively, and what practical benefits it delivers for engineers, installers, and end-users.

Why modularity matters in electrical systems

A modular electrical system is based on standardized, pre-engineered, or semi-prefabricated components that allow fast configuration, easy future modifications, and efficient maintenance. But why is this important?

Key Benefits

- Reduced design and installation time: libraries, predefined modules and ready-to-use components reduce custom work.

- Higher system flexibility: the ability to expand or modify the system without reworking the entire distribution layout.

- Simplified maintenance: predefined tap-off points and accessible routing make servicing easier and faster.

- Improved reliability and quality: modular systems reduce installation errors, downtime and compatibility issues.

Graziadio’s busbar systems are designed specifically to maximize these benefits:

they allow fast “plug & play” assembly, offer high protection ratings (up to IP68 for selected ranges) and can be reconfigured or extended even many years after installation.

Typical challenges such as space constraints, high power distribution, complex routing and compliance with electrical safety standards can therefore be addressed efficiently through modular system design.

The role of BlindoCad in modular system design

BlindoCad is a strategic tool within the electrical engineering workflow. It transforms conceptual layouts and preliminary diagrams into accurate technical system drawings, directly aligned with Graziadio’s busbar product lines.

Software Overview

Software Overview

- Fully integrated in AutoCAD and compatible with several CAD / CAD-based platforms.

- Enables full 2D and 3D system design including routing, elevation changes and mechanical support integration.

- Includes continuously updated product libraries from Graziadio (GLS, J Series, GDA/GDR, K Series, ISOLSBARRA).

- Automatically generates a Bill of Materials (BoM) with quantities, lengths and accessory codes.

- Continuously updated to support new system configurations and technical requirements.

BlindoCad is therefore not just a drawing tool, it acts as a design engine, improving standardization, reducing errors, and streamlining the transition from engineering to on-site installation.

Step-by-step: designing a modular electrical system with BlindoCad

Below is a general workflow (adaptable to each project) that guides the process from initial definition through final execution.

1: Define technical specifications

- Determine the required current rating (e.g., 630 A, 2000 A, 5000 A) and select the appropriate Graziadio busbar family (e.g., GDA for 63–2500 A).

- Check installation conditions: indoor/outdoor, required enclosure rating (IP66, IP68), environmental constraints.

- Define the routing strategy: feeder, distribution points, risers, distances, support structure.

Step 2: Create the base 2D layout

- Open BlindoCad and select the busbar series from the product library.

- Draw straight sections with standard or custom lengths.

- Insert elbows, T-junctions, vertical/horizontal transitions and end feeds.

- Add tap-off boxes, expansion elements, supports and terminal units from the library.

Phase 3: Convert to 3D and verify

- Switch to 3D mode to check spatial clearance and alignment with architectural/plant structures.

- Detect and solve potential interferences before installation.

- Validate mechanical support spacing, load constraints and routing intelligibility.

Step 4: Select product configuration and finalize design

- Insert the correct busbar system (e.g., ISOLSBARRA for 630–6300 A systems).

- Adjust editable parameters: conductor material (copper/aluminium), end-feed type (P / TT), support hardware.

- Confirm electrical and mechanical compatibility of each component.

Phase 5: Generate the BoM and documentation

- Generate the Bill of Materials automatically with one command.

- Export drawings, exploded 3D views and installation details for contractors.

- Refer to the official Installation & Uninstallation Guide for software setup.

Step 6: Installation and field implementation

- Modular busbar design reduces installation time and on-site errors.

- Pre-engineered support elements streamline assembly.

- System expansion is fast and cost-effective thanks to modular continuity.

Watch the tutorial:

How to draw a busbar line in BlindoCad

Benefits and practical application

Using BlindoCad and Graziadio’s modular busbar systems results in:

- Faster design and installation processes

- Fewer errors and reduced rework

- Scalable systems ready for future expansion

- Proven reliability backed by decades of Italian industrial expertise

- Lower maintenance effort and minimized downtime

Best Practices

- Keep BlindoCad libraries up-to-date with the latest product revisions.

- Confirm CAD platform compatibility prior to installation.

- Plan tap-off points early for future flexibility.

- Include exploded drawings and assembly sections in installation documents.

- Verify enclosure rating, grounding requirements and support spacing.

Conclusion

Conclusion

Designing a modular electrical power distribution system using BlindoCad and Graziadio busbar solutions offers a strong competitive advantage.

For newcomers, it provides a guided approach; for experienced engineers, it significantly streamlines the workflow.

Book a technical call with our engineering team.